Jungheinrich Double Reach Forklifts Dallas

Forklift Material Handling

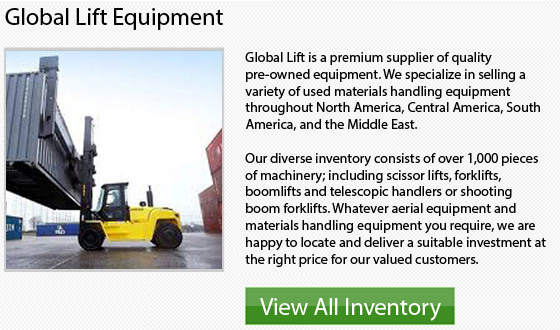

Companies could go through changes in their material handling requirements eventually. Things such as expanded geographical coverage, more SKUs, and need to lessen inventories demand process review to be able to maintain optimal productivity. There have been lots of advances within material handling technologies and processes during the last several years. Several tools are evolving at a very fast rate and have the potential to considerably effect profitability.

Lift Truck Battery & Charging Technology

Now is the perfect time to think about converting from conventional, internal combustion lift trucks to electric lift trucks. The technology behind modern electric forklift charger and battery combinations is well ahead of the technological curve. Electric systems can provide more power for longer periods than ever before. The current series of electric forklift models offer run-times and capacities which surpass older units. Advancements in both battery and charger technologies help contribute to more environmentally sound methods in factories all over the globe.

The lithium-Ion batteries are considered the wave of the future because this key new technology is have a revolutionary impact on the use of electric forklifts. The benefits of Li-ion batteries are run times and low maintenance and size. They can be produced in smaller sizes than traditional lead acid batteries and are capable of holding up to six times the charge. They have zero memory, that enables them to maximize charging.

Internal Combustion or Electric Lift Truck

Whether you are replacing an existing truck or searching for your very first forklift, consider investing in an electric lift truck. Remember that the legislative, environmental and technological issues involved in forklift usage and technology is subject to change. Please review this easy-to-follow guide when thinking about whether an IC or an electric truck best suits your requirements.

- Mitsubishi Forklifts Dallas

Even if there are numerous companies who begin employees in the receiving area, they would be much better off to assign pro's to deal with the put-away jobs. Experienced people who really understand and know... More - JLG Straight Boom Lifts Dallas

JLG provides the 600 Series of articulating booms. These units feature a narrow chassis option to access confined areas. The 600 Series showcases the best work envelope within the industry; a horizontal outreach of 12.12... More - Daewoo Dual Fuel Forklifts Dallas

Basic Fuel Types of Forklifts Forklifts are powered lift trucks which are utilized in a wide variety of industries to move heavy materials and products. Forklifts are tough and dependable machines that are necessary tools... More - Haulotte Straight Boom Lifts Dallas

Telehandlers are heavy duty work machines produced specifically to operate in rough environment. This however, does not mean they can be driven without regard on rough terrain. These kinds of machinery have a much bigger... More - Doosan Diesel Forklifts Dallas

Forklift Engines Forklifts are classified as small-engine vehicles. Forklift engines all follow the principles of internal combustion, while the numerous makes and models of lift truck would have a different layout and design. Forklifts are... More